BRIEFDESCRIPTION

AASTMT plays a leading role in wastewater discharge management in Egypt by fully complying with national regulations and aligning with international environmental standards. Its comprehensive framework ensures that wastewater is collected, treated, and safely disposed, while potable water remains strictly separated and safeguarded. Through awareness programs, stakeholder engagement, and certified hazardous waste disposal, AASTMT demonstrates its commitment to sustainable water management and environmental stewardship. By integrating infrastructure, policy, research, and awareness, AASTMT sets a benchmark for Egyptian universities in managing water responsibly, protecting ecosystems, and contributing to the Sustainable Development Goals (SDG 6: Clean Water and Sanitation, SDG 12: Responsible Consumption, and SDG 15: Life on Land).This document is a thorough framework for regulating rainwater and wastewater outflow. In order to provide ecologically responsible water management throughout campus facilities, it provides system specifications, sustainability-focused solutions, combining system functionality with SDG-aligned practices to minimize environmental impact.

System Description:

Effective water management is crucial to AASTMT's commitment to sustainability and achieving SDG 15. The sewage plant and rainwater system at Abu-Qir, Alexandria, is designed to handle wastewater and rainwater from specified areas, excluding student housing, hotels, presidential buildings, and restaurants.

The drainage networkL:

Extending between these buildings and reaches the wastewater and rainwater collection pit located behind the buildings of the College of Architecture and Computers. Through a slope line with a diameter of (12 inches) and the current cesspool with dimensions of (2 x 2 meters).

Sump Specifications:

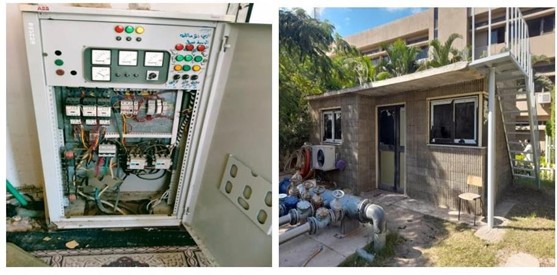

Pump Room Specifications:

Submersible Pumps:

Pump Room

Control Room

The battery and the Field

Valves

Validation criteria | Validation method | Frequency | |

System capacity | Sump must handle up to 12 cubic meters. | Capacity Test | Bi-annual |

Pump flow rate | Each pump should discharge 60-70 cubic meters per hour. | Flow Rate Test | Monthly |

Battery and valve configuration | Check valves and shut-off valves should operate smoothly and regulate discharge effectively. | Functional check | Monthly |

Control panel operation | Control panels must manage discharge flow and respond to real-time system monitoring. | Operation test | quarterly |

Discharge water quality | Water should meet pH, turbidity, and pollutant standards. | Quality Testing (Lab Analysis) | Monthly |

Routine maintenance | Routine Maintenance Bi-annual inspection of sump, pump room, and valves must be conducted. | Visual and Functional Inspection | Bi-annual |

Task | Responsible party | Role |

Daily Cleaning and Disinfection | Contracted Company (Workers & Plumbers) | Ensure pipes are clear to prevent blockage. |

System Monitoring | Control Room Operators | Monitor pump operations and discharge flow |

Routine Inspections | AASTMT Maintenance Team | Conduct bi-annual inspections. |

Authorization and Oversight | AASTMT Facilities Management & Maintenance Team | Oversee system authorization and compliance. |

Stakeholder Engagement Workshops | SDG 6 and 15 officers | Coordinate with environmental organizations. |

Document title | AASTMT Standards and Guidelines for Discharge of Waste Water-updated guidelines (2025 Reviewed) ‘’A Supplementary Report to the Institutional Policy” |

Date Created: | August 2023 |

Approving Body: | SDGs Workforce Committee |

Version: | 2 |

Last Review Date | 2025 |

Next Review Date: | 2026 |

Document Owner: |

|

Lead Contact: | Prof. Dr. Kareem Tonbol TA. Elen Emad Officer. Ragga Ahmed |

Approval Signature | Dean of Scientific Research and Innovation |

Supplementary Report to the AASTMT’s Standards

and Guidelines for Discharge of Wastewater

AASTMT aligns its water management systems with Egyptian governmental authority regulations to prevent polluted water from entering natural watercourses. The framework reflects both mandatory national standards and international best practices

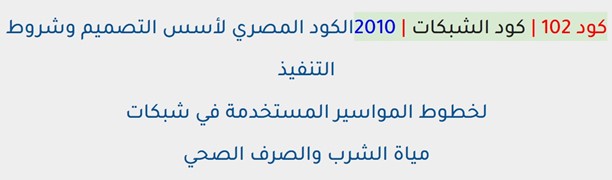

AASTMT strictly enforces the Egyptian Code 102 (2010) for the Design and Implementation of Drinking Water and Wastewater Networks, ensuring safe separation of potable water from wastewater systems:

Dual Pipeline Systems: Distinct pipelines are used for potable water and wastewater across all facilities, preventing cross-contamination.

Backflow Prevention Devices: Installed and regularly maintained to prevent wastewater re-entering potable systems.

Routine Inspections and Audits: Regular inspections cover potable water pipes, wastewater lines, valves, sewage manholes, rain gutters, and building roofs.

Potable water is stored in separate tanks isolated from sewage lines, with designated monitoring systems to ensure supply safety.

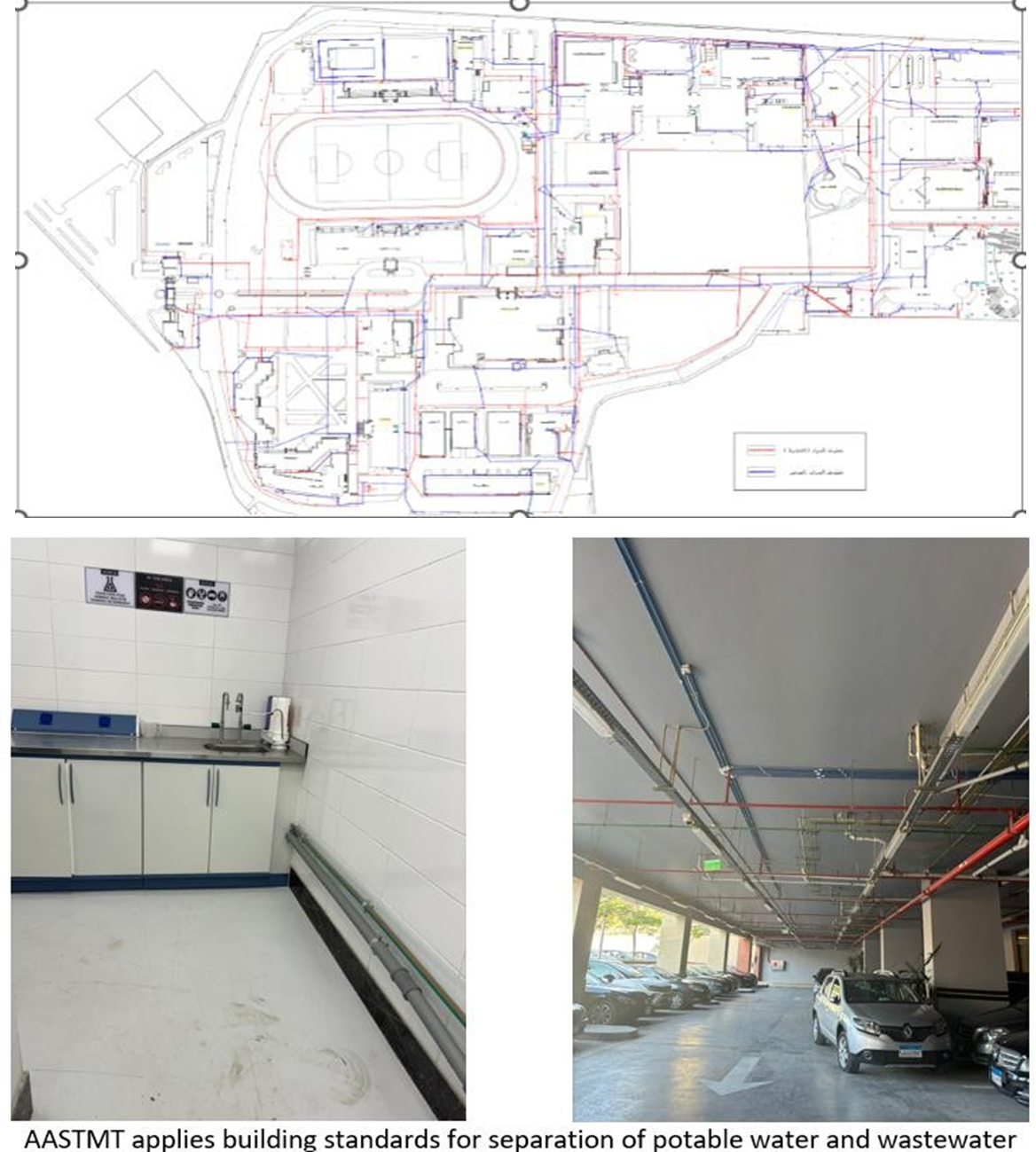

Wastewater systems are equipped with backup control panels that prevent overflow or accidental discharge in case of failure. Visual plans and schematics at AASTMT illustrate potable (red) and wastewater (blue) pipelines, ensuring clarity and compliance. Laboratory systems also demonstrate color-coded separation (green for potable water, grey for drainage

AASTMT’s wastewater management approach demonstrates full compliance with national environmental standards and guidelines, as all wastewater is directed to government-operated treatment facilities in accordance with Egyptian Standard No. 44 (2000) and Law No. 93 (1962). This ensures that all treated effluents meet the required discharge standards for environmental protection. By integrating these regulatory frameworks into its institutional sustainability policy, AASTMT reinforces its commitment to responsible wastewater management, environmental stewardship, and active contribution to SDG 6 (Clean Water and Sanitation) and SDG 13 (Climate Action).

AASTMT implements a comprehensive hazardous waste disposal system to protect water quality from laboratory pollutants:

Waste Collection and Storage: Laboratory waste is segregated into chemical and biological waste streams and temporarily stored in controlled campus facilities.

Certified Disposal: Disposal is conducted twice weekly by Nahdet Misr, a certified company, under contracts adhering to Egyptian hazardous waste laws.

Safe Disposal Sites: Wastes are transferred to the Alexandria Governorate Hazardous Waste Management facility, ensuring safe treatment and disposal.

Regulatory Compliance: Laboratory waste management is governed by Egyptian legislation and aligned with

This system prevents harmful chemicals, biological agents, and pollutants from contaminating water sources.

AASTMT integrates its water discharge framework into broader environmental management standards, including:

AASTMT reinforces its technical standards with awareness initiatives, funded projects, and stakeholder workshops: